About Metalsmithing

About Metalsmithing

Metalsmithing is the process of creating jewelry through the manipulation of various metals. These manipulations include forming and shaping, sawing, doming, foldforming, drilling, soldering, texturing, stamping and more. Metalsmiths are considered a "jack of all trades". Here you will learn about metals and metalsmithing techniques.

Popular Metalsmithing Techniques

Annealing

Annealing is the process of reducing stress within metal by heating it with a torch or kiln. Annealing is needed to soften metal before bending it, making it much easier and less risk of damaging the metal. After heating the metal, quench into water to cool, then place into pickle to dissolve surface oxides.

Soldering

Metals are most often joined together by soldering. Solder is a metal alloy with a lower melting point than the metals it is joining. At soldering temperatures, the crystals of metal move apart, opening up microscopic spaces. Soldering introduces an alloy that is fluid exactly at the point of maximum crystal expansion. The solder flows into the spaces to create a bond.

Forging

Forging is a technique that uses controlled hammering to deform and shape metal.

Chasing & Repousse

Repousse is one of the oldest metalsmithing techniques in the world. Repousse is a technique in which a malleable metal is shaped by hammering from the reverse side to create a design in low relief. Chasing refers to a similar technique, in which the piece is hammered on the front side, sinking the metal. The two techniques are often used in conjunction.

Sinking

Sinking is a technique used to create domed forms in sheet metal by pounding the metal into a hemispherical die.

Metals

Sterling Silver

Sterling is the most commonly used alloy in jewelry making, and known for its inherent strength. Sterling Silver contains 92.5% by weight of silver and 7.5% by weight of other metals, usually copper. Sterling silver is more prone to tarnishing, and elements other than copper can be used in alloys to reduce tarnishing, as well as casting porosity and firescale. Such elements include germanium, zinc, platinum, silicon, and boron. Recent examples of alloys using these metals include argentium, sterlium, sterilite and silvadium. In recent years, a number of alternate sterling alloys have been patented.

Sterling Silver Melting Point: 1640°F / 893°C

Fine Silver

Fine Silver has a millesimal fineness of 999. Also called pure silver, or three nines fine, fine silver contains 99.9% silver, with the balance being trace amounts of impurities. Fine Silver has a limited range of applications because it is so soft, but should be used for setting fragile stones in settings where not much force can be used.

Fine Silver Melting Point: 1761°F / 960.5°C

Gold

The purity of gold is described in karats. High-karat golds (24 and 22k) are very soft and malleable, and have a rich yellow color. Lower-karat golds are alloyed with greater proportions of other metals, allowing different working properties and colors, such as white, red or green-gold. Because of the high cost of gold, it is often used for contrasting color or accents on silver pieces.

Gold Melting Point: 1945°F / 1063°C

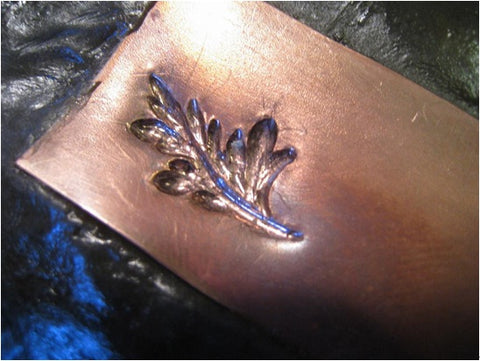

Copper

Copper is a soft, malleable, and ductile metal with very high thermal and electrical conductivity. It is a good metal for making large pieces that are heavily formed, but too soft for thin, intricate forms. Copper is a reactive metal and quickly oxidizes in air. This characteristic allows many color variations to be created through heat and patina.

Copper Melting Point: 1981°F / 1083°C

Brass

Brass is an alloy of copper and zinc. Brass is very rigid once work-hardened, though it can easily be overworked and requires regular annealing. Brass can achieve a wide range of properties and colors.

Brass Melting Point: 1750°F / 954°C

Bronze

Bronze is an alloy consisting primarily of copper, commonly with about 10-20% tin. Bronze is mainly used for casting as it is very hard, and will retain a very high degree of detail. It can also achieve a wide range of colors. To distinguish between brass and bronze, dissolve a small sample in a 50/50 solution of nitric acid and water. Tin can then be indicated by the white precipitate.

Bronze Melting Point: 1886°F / 1030°C

Nickel

"Nickel Silver" contains roughly 60% copper, 20% nickel and 20% zinc. Nickel is used in jewelry because of its low cost and working properties. It can be cast, however, due to its high melting point and tendency to oxidize can make this difficult.

Nickel Melting Point: 2651°F / 1445°C

Steel

Steel is an alloy of iron and carbon. The higher the carbon content, the harder the steel will be. Steel can be soldered to steel and other metals using silver solder. There are different types of steel, including stainless steel, tool steel and mild steel.

Mild Steel Melting Point: 2759°F / 1515°C